5s Methodology & Principles in Project Management

Organizations often try to change their production system to achieve more work using fewer resources. In order to increase the profit by reducing waste and costs, a business must become more productive than before considering the rapidly changing economic conditions. In other words, in order to improve productivity, organizations must implement efficient methods for production. 5s Methodology and 5s Principles can be used to organize the production system to create products by using less time and costs. The 5s methodology offers many solutions to maintain an efficient, clean, and safe work environment. This article discusses the benefits of using 5s in the workplace and answers, what does the 5 s stand for?

Table of Contents

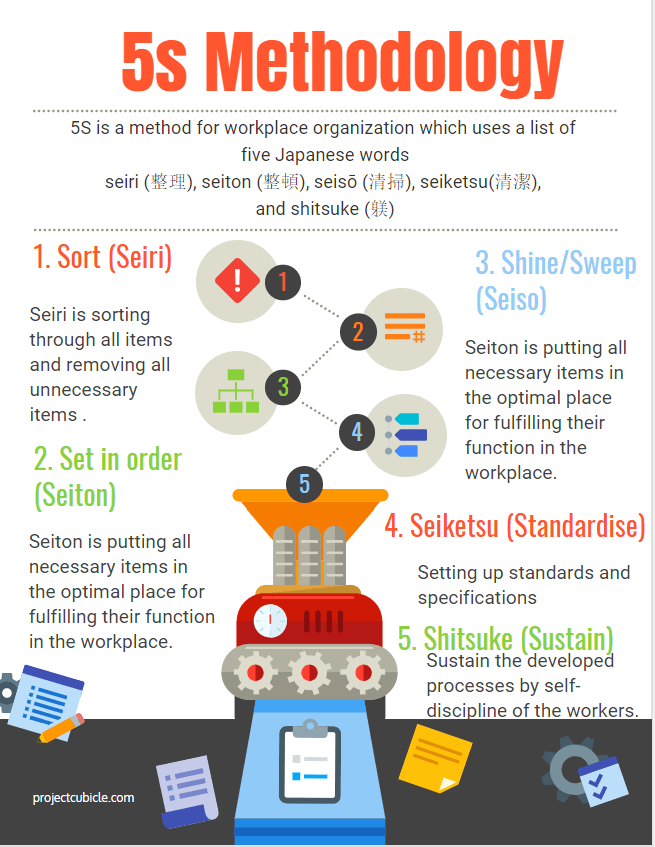

What is 5s Methodology?

5s is one of the most popular tools used to improve the production system. Simply put, 5s is a lean manufacturing tool for organizing the workplace efficiently and effectively, and safely. The 5s methodology has 5 phases which use a list of five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke. This tool enables to organize workspace clean by eliminating waste and putting everything where it belongs to which helps workers to perform the tasks without wasting time or risking injury.

The Concept of 5s Methodology

The 5s methodology is an innovative management system that encourages the team members to think lean and provides the adoption of Lean principles in the company. While implementing the Six Sixma Methodology, 5s principles can be used for reducing waste. In order to have a clean workplace and/or high performing process, principles of 5s methodology can be used.

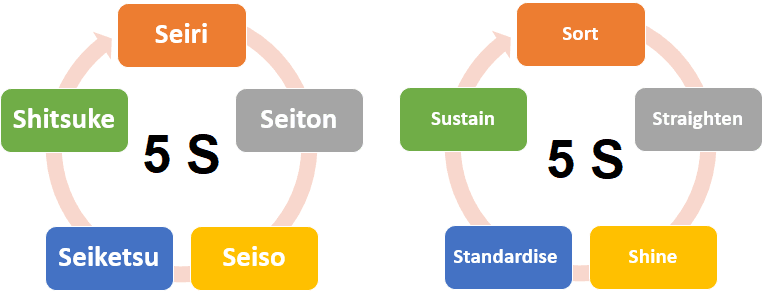

What Does the 5s stand for?

What does the 5s stand for? The name of the methodology is 5s because it includes 5 basic phases: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. Each word begins with the letter “S”; (Seiri, Seiton, Seiso, Seiketsu, Shitsuke) hence the name is 5 S.

The 5 Phases are as follows:

• Seiri: Sort

• Seiton: Straighten

• Seiso: Shine

• Seiketsu: Standardise

• Shitsuke: Sustain

Phase 1: Seiri

The first phase of the 5s Methodology is Seiri. Seiri (Sort) represents to remove or eliminate unnecessary items such as outdated materials, broken equipment which is not needed in the workspace. Also, this phase involves classifying all equipment and materials by frequency to use. The main benefit of the first step is that you can get rid of waste so that you won’t have to waste time searching for the things you need. This will increase your productivity and efficiency by saving time.

Phase 2: Seiton

Seiton (Straighten or Set in Order) represents to arrange items and identify their locations so that it will be easy to find and to use when needed without wasting time. Arranging items by their functions, dimensions, and purposes enables to use them quickly when needed. Arranging items according to their uses make workflow easier.

Phase 3: Seiso

Seiso (Shine / Sweeping) represents to clean the worksite, equipment, and tools on a regular basis and remove dirt and dust from the workspace. Cleaning activity is necessary for health and safety and it should be a regular activity. Prevent machinery and equipment deterioration and corrosion extends their economic life. A clean work environment motivates the employees and prevents them from accidents.

Phase 4: Seiketsu

The Seiketsu (Standardise) involves setting up standards and developing specifications for 5s implementation. Seiketsu consists of building a strong set of procedures to maintain the 5s system. Every process should have a standard and high standards should be maintained in the workplace. Everybody in the work environment should be aware of their responsibilities for performing the first 3s: sorting, organizing, and cleaning. Regularly using audit and control checklists are the essential components of the Seiketsu process.

Phase 5: Shitsuke

Shitsuke (Sustain) represents to have a long-term and continuous improvement system. Responsibilities should be established, maintained and team meetings should be held regularly. Audits and training should be done regularly. The main goal of this process is to maintain the 5s principles in the work environment.

Benefits of 5s Methodology in the Workplace

5s Methodology provides continuous improvement to the processes. Regularly revisiting the 5s method maintains the improvements over the long term.

There are lots of benefits of 5s. A few benefits of this methodology are listed below.

- Reduces direct costs and indirect costs

- Helps to create a safer work environment

- Helps to create a clean work environment

- Increases efficiency

- Improves employee and customer satisfaction

- Creates a culture for the organization

- Provides a clean and safe work environment.

- Reduces equipment breakdown

- Decreases in flow distance

- Increases floor space

- Reduces hazards

- Increases employee morale

Summary

In this article, we discussed the benefits of 5s in the workplace and answered what does the 5s stand for. Just like the Kaizen Methodology or Lean, the 5s methodology was developed in Japan with the focus on increasing the profit with reducing waste and cost by organizing the work environment.5s Methodology is a foundation of kaizen, which refers to activities that continuously improve all functions and involve all employees in an organization. 5s is one of the most cost-effective lean techniques which is applicable in all sectors. Work can be done efficiently and safely, problems can be solved quickly by the help of this tool. If the 5s Methodology is implemented correctly, it helps project managers and project teams save time, budget and effort. The main benefit of the 5s methodology is its simplicity. It does not require a difficult system and analysis. Almost all type of organizations across all the industries may have the benefits of using the 5s methodology. Principles of the 5s are applicable to companies ranging from small offices to international companies.

See Also

External Reference

Since 2004 I work for ICT Management which provides worldwide quality management service. Passionate about new technologies, i have the privilege to implement many new systems and applications for different departements of my company. I have Six Sigma Green Belt.

When someone writes an article he/she maintains the thought of a user in his/her mind that how a user can understand it.

Therefore that’s why this post is perfect.

Thanks!