Lean Project Management and Lean Methodology

Lean project management covers a wide spectrum of concepts such as lean manufacturing, lean thinking, lean construction, etc. Basically lean methodology or production aims at eliminating wastes and other processes which are not adding value to the production system. Although this philosophy was developed in the Toyota Production System, many project teams in various industries use lean tools and techniques to improve their processes. Industries such as software, healthcare, finance, construction, business, defense, etc. may gain the same kind of benefits that lean has achieved for manufacturing. In this article, we will discuss the benefits of lean project management methodology to organizations.

Table of Contents

Main Principles of the Lean Project Management and Lean Methodology

Many projects are behind the work schedule and/or over budget. Lean project management can be described as applying lean manufacturing principles to the area of project management. To that end, project teams might establish a system to perform all the activities throughout the entire project life cycle with the help of lean principles. For example, standardizing tasks if possible helps project teams to shorten the duration of activities and limit resource usage. Performing similar tasks improves the performance and efficiency of the project.

Understanding each activity and process helps to identify the origins of wastes and non-value-added processes. The keystone of Lean methodology is to improve profit and customer satisfaction by maximizing value and minimizing wastes. Lean project management methods include Kanban, Lean Six Sigma, Deming Cycle to guide teams on the paths of continuous improvement.

Recommended Article: What is Lean Six Sigma Methodology?

3M’s (Muda, Mura, Muri) in Lean Manufacturing

Muda, Mura, and Muri are the 3M’s that are widely used in the Toyota Production System and later on the concept of Lean to describe wasteful practices to be eliminated.

Muda (無駄): is the wastefulness, uselessness, non-value-adding work. The term “Muda” covers seven types of wastes. Below are the seven Muda’s

- Transport

- Inventory

- Motion

- Waiting

- Over-Processing

- Overproduction

- Defects

Mura (斑): is unevenness. Mura is the root cause of Muda. Because unevenness and irregularity cause wastes.

Muri (無理): is overburden. Muri is overloading equipment and overusing the workforce beyond their limits. Muri might be a result of Mura.

It is not very easy to identify all the wastes in the working environment. This increases the potential for risks to arise. Elimination of waste is the main purpose of lean.

Lean Thinking

Before discussing the basics of lean project management, let’s take a look at the lean thinking concept.

Lean thinking aims at creating a continuous value stream by using the project resources effectively, reducing wastes, and ensuring customer satisfaction by adopting the principles of lean manufacturing. James P. Womack and Daniel T. Jones are the founders of the Lean Enterprise Institute (LEI). They recommend five principles in their book: Lean Thinking: Banish Waste and Create Wealth in Your Corporation to help organizations achieve success.

Lean thinking was born in the manufacturing industry and influenced other industries like software, healthcare, construction because lean is an approach that affects everything an organization does.

Main Principles of Lean Thinking

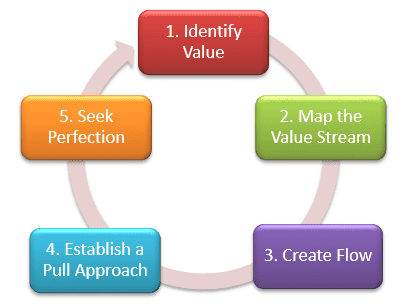

Lean thinking has an important place in lean project management. Womack and Daniel T. Jones defined the five basic principles of lean thinking in their book “The Machine That Changed the World” in 1990.

These principles are;

- Value (Identify Value): The first principle is understanding the value of a product from the customer’s point of view. The organization must understand what value the customer places upon their products and services. Determination of the value is based on the customer’s needs for the product.

- Value Stream (Map the Value Stream): Value stream is the entire flow up the product’s life cycle from raw materials through to the customer’s use. Creating a value stream map using visualization techniques, diagrams and charts is helpful to demonstrate the sequence of activities required to deliver the end product.

- Flow (Creat Flow): The Main goal of this step is to improve the value stream and ensure that the value stream flows. Waste should be removed from the flow of the value stream. If the value stream stops at any point, waste may occur.

- Pull (Establish a Pull Approach): If the flow of the value stream is improved, time to customer can be improved. The pull principle helps to be sure that nothing is made ahead of time. In traditional manufacturing, approach products are manufactured based on a schedule or forecast. But in the pull approach, the product is not manufactured until the customer orders it. As a result of this approach, you don’t need to store a large number of products.

- Perfection (Seek Perfection): The perfection step is one of the most important steps. The lean system requires continuous improvement and continuous improvement brings perfection because lean is a live process. Lean thinking should be every employee’s business and every process should be involved in lean.

The below figure illustrates the five principles of lean thinking.

Benefits of Lean Project Management and Lean Methodology

Lean manufacturing uses fewer resources compared with traditional production or mass production. Human effort, floor space, duration is decreased based on the effective use of lean principles. Below are some benefits of lean project management methodology.

- Develops a culture of empowerment

- Reduces manufacturing lead time

- Standardizes tasks to make project performance improvement

- Helps to complete the project on time and budget with meeting customer requirements.

- Reduces costs

- Reduces inefficiencies and unproductiveness

- Improves the quality of product

- Improves customer satisfaction

- Improves profit margin

- Helps to avoid scope creep

- Helps to understand the customer value better

Conclusion

Project management processes can be improved with the help of lean principles. A project can be thought as a value stream from the project manager’s point of view. Then the customer requirements and satisfaction should be specified. The project team members must enhance the working environment by specifying and eliminating wastes in all the processes. Deming Cycle, 5 Why’s, Kaizen, 3M’s can be used to improve the processes for production.

In this article, we discuss the benefits of lean project management methodology. Note that lean is an important concept in project and product management.

External References

“The Machine That Changed the World” Womack, Daniel T. Jones

See Also

Project Management Methodologies

Margaret Conte has been working as a consultany for over 15 years. In this time, she has worked in a variety of project management methodologies (waterfall/scrum/agile) and has been a strategic Project Manager, Coordinator, Facilitator and Scrum Master. She is the co-founder of Development Fast Academy