5 Whys Technique, 5 Why Analysis and Examples – projectcubicle

In the world of business and continuous improvement, finding the root cause of a problem is crucial for achieving long-term success. One of the most effective problem-solving methodologies is the “5 Whys” technique (5 Why Analysis). In this article, we will delve deep into the 5 Whys technique, its history, application, and provide you with real-world examples to illustrate its effectiveness.

Table of Contents

Understanding the 5 Whys Technique

The 5 Whys technique is a simple yet powerful method for identifying the underlying causes of a problem. It originated in Japan and is closely associated with the Toyota Production System, a renowned framework for lean manufacturing and process improvement. The core principle behind the technique is to ask “why” multiple times (typically five) to drill down to the root cause of an issue.

What is 5 Whys Technique?

5 Whys is a technique used to determine the root cause of a problem by repeatedly asking the question “Why”.

The technique was developed in the 1930’ s by Mr. Sakichi Toyoda who is the founder of Toyota Industries and then became a worldwide technique that is used by Toyota and many other companies today.

Basically, the 5 Whys relies on asking “Why” several times to understand all the signs of a problem. It is often used in conjunction with other techniques such as fishbone diagram, six sigma DMAIC, and Deming Cycle (PDCA).

The History of the 5 Whys Technique

The 5 Whys technique was developed by Sakichi Toyoda, the founder of Toyota Industries, in the early 20th century. Toyota’s success in manufacturing and quality control is partly attributed to the widespread adoption of this method. Over time, the technique gained recognition beyond the automotive industry and became a valuable tool in various sectors, including healthcare, aviation, and software development.

Application of the 5 Whys Technique

The versatility of the 5 Whys technique makes it applicable to a wide range of scenarios. It can be used in:

1. Manufacturing

In manufacturing, identifying the root causes of defects, equipment breakdowns, or production delays is essential for maintaining high-quality standards and efficiency. The 5 Whys technique helps uncover the systemic issues that lead to these problems.

2. Healthcare

In the medical field, patient safety is paramount. The 5 Whys technique aids healthcare professionals in investigating medical errors, reducing patient harm, and improving overall healthcare processes.

3. Business Operations

Businesses often face challenges such as declining sales, customer complaints, or operational inefficiencies. By applying the 5 Whys technique, organizations can pinpoint the reasons behind these issues and develop strategies to address them effectively.

4. Software Development

In software development, debugging and resolving issues are routine tasks. The 5 Whys technique assists developers in understanding the root causes of software bugs and streamlining the development process.

When to Use this Technique?

The 5 Whys technique can be used for troubleshooting, improvement, and problem-solving purposes. Whenever a system or process doesn’t work properly, you can implement this technique to develop a solution. It can be used during the analysis phase of the DMAIC, plan phase of the PDCA, identify and eliminate the phase of lean manufacturing.

On the other hand, it is suitable for simple problems rather than complex ones. Because this technique directs you to track one or limited paths when, in fact, there might be several causes. In such circumstances, it can be a good idea to use 5 whys along with a fishbone diagram and/or Failure Mode and Effects Analysis (FMEA).

5 Whys is widely used because of its simplicity and flexibility. You can find the root causes quickly on the first try. Hence, when you spot a problem, try it before using a more detailed technique.

How to Perform 5 Why Analysis?

Below steps can be followed for making a 5 Whys analysis.

Step 1. Assemble a Team

A team should be formed in order to conduct a brainstorming session to detect the root cause of the problem. To make the brainstorming more effective, team members should be familiar with the details of the problem. Thus, they can bring their expertise and viewpoint by asking crucial questions.

Step 2. Define the Problem

Defining the problem clearly is the first thing in the 5 Whys technique that the team should do. In this step, the problem should be defined clearly and a concise problem statement should be written. If the problem statement is clear and explanatory enough, the team will spend less time on resolving it.

At this step, the scope of the problem should also be determined. The scope of the problem should reflect the size and characteristics of the problem. If the scope of the problem is large, you will need extensive improvements to the problem. If the scope is narrow, improvements could be smaller. Creating a digital report of the situation can help keep your scope from getting too large, while also ensuring that nothing falls through the cracks.

Step 3. Ask “Why?”

In this step, the team leader asks the team “Why” the problem occurred and the team answers the question. Then the team leader asks if the identified causes were corrected, could the problem still occurs. If the team answers “Yes”, then the team leader should ask “Why” again.

Sometimes the root cause can be identified in the third or fourth “Why” and in some cases, it can not be identified in the fifth “Why”.

The responses of the team members should focus on the process and system errors. Their responses should not be affected by their biases and emotions. Otherwise, results may be misleading.

If you detect more than one reason for the root cause of the problem, repeat this exercise for each reason to find the root cause for each one.

Step 4. Determine and Implement Corrective Actions

Once the root causes are identified, a list of appropriate corrective actions should be created to address each. At this step, the master assigns responsibility for the corrective actions to the participants in the discussion.

Note that there is no specific format used to document the 5 Whys exercise. Some organizations use their own detailed formats, others use various frameworks.

Simple 5 Why Examples

For a better understanding of the 5 Whys technique (5 why example), let’s review the examples below.

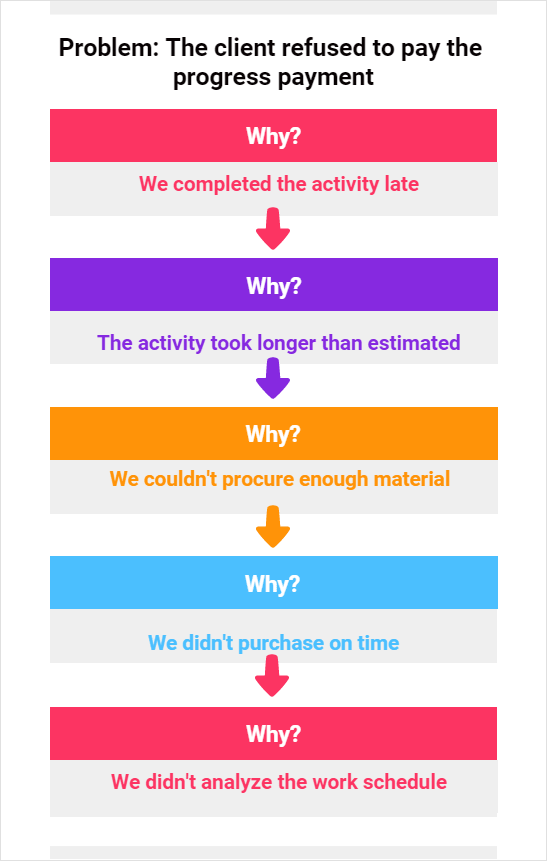

Problem statement – The client refused to pay the progress payment.

- Why did the client refuse to pay the progress payment? Because we completed the activity late.

- Why did we complete the activity late? Because the activity took longer than estimated.

- Why did the activity take longer than estimated? Because we couldn’t procure enough material for the activity.

- Why didn’t we bring enough material? Because we didn’t purchase on time.

- Why didn’t we purchase the materials on time? Because we didn’t analyze the work schedule.

The root cause of the problem is that we didn’t analyze the work schedule. Corrective action is to create good communication channels within the project team and assemble progress meetings regularly to avoid a lack of communication and coordination.

The below figure illustrates 5 Whys Example.

What are the Key Benefits of the 5 Whys Technique?

- It helps to determine the root cause of a problem

- It helps to identify more problems during the performance of 5 Whys analysis for a problem.

- It encourages team members to share their ideas and expertise

- It is an effective tool that is very easy to use

- It improves decision making

Summary

If you don’t analyze the root cause of a problem properly, you can not resolve it and it would return back in another form. Repetitious issues are often the predecessors of big problems. Although temporary solutions are easy to apply, they often become useless if the problem arises again.

In this article, we analyzed the 5 Whys technique (5 why example) ith the help of an example. Basically, the 5 Whys analysis is an effective tool for determining the root cause of a problem. It can be used as a part of “The Fishbone Diagram” for problem-solving. Also, this technique is widely used in the analysis phase of the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) practices.

Thank you dear reader!

If you want, you can share your experience and knowledge related to 5 Whys by using the comments box below.

External References

See Also

11+ years strategic communications, marketing, and project management experience. I am a trainer at StarWood Training Institute, focusing on online courses for project management professionals.

I found this post to be incredibly insightful! The 5 Whys Technique is something that I’ve never heard of before, but it makes so much sense. I love how you provided examples to illustrate the process. It’s amazing how something as simple as asking ‘why’ five times can reveal the root cause of a problem. I’m definitely going to start using this technique in my work and personal life. Thank you for sharing!