What Are The Most Common Risks In Supply Chain Management?

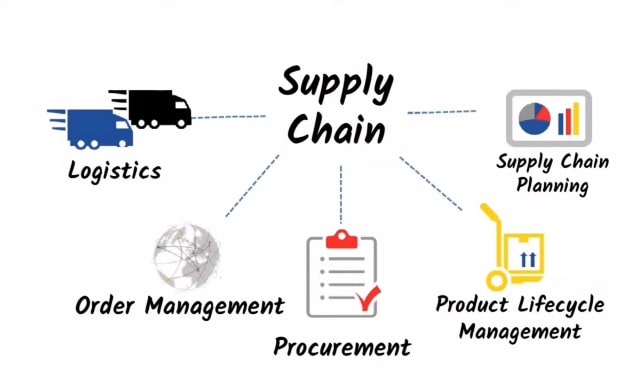

Supply chain management is an essential component of any business. It manages and streamlines the flow of goods and services while maintaining quality, speed, and customer satisfaction from production to final delivery. Many businesses rely on a complex network of suppliers, manufacturers, and distributors to get their products to market. As such, supply chain management isn’t without risks for both small business owners to large corporations. There are several internal and external issues identified within the sector that can regularly influence and impede business operations. Here are the most common risks in supply chain management:

Table of Contents

Cybersecurity Risks of Common Risks In Supply Chain

While digitization has improved supply chain operations and efficiency, it’s also increased the risk of cyberattacks. Online systems are vulnerable to cyberattacks that could destabilize and bring down a supply chain network through implanting malware, ransomware, and hacking.

This also poses a significant threat to routes that serve sensitive locations such as a defense industrial base supply chain, government facilities, and national security points. These could be targeted by terrorism that can compromise data protection, automated machinery, and autonomous weapons. Thus, supply chain management enacts prevention methods such as privilege access, network segmentation, and implementing up-to-date supplier security protocols.

Cybersecurity threats can lead to data breaches, theft of intellectual property, and disruption of operations. This can be caused by inadequate cybersecurity measures or third-party vulnerabilities.

Regulatory compliance:

Failure to comply with regulations can result in fines, legal action, and damage to brand reputation. This can be a result of inadequate understanding of regulations, lack of compliance training, or inadequate record-keeping.

Geopolitical Risks

Supply chain companies are greatly impacted by political situations, government policies, trade deals, laws, and regulations that could change anytime. These create volatility and impact how and where operations can occur as well as the manufacturing and movement of goods across a country or the globe.

They could also make it difficult to source raw materials, change labor practices, and adapt to a new business culture and environment. Additionally, geopolitical risks are subject to civil unrest, wars and conflict, political instability, and bureaucracy that can slow down or suspend operations indefinitely and lead to supplier business closures in those locations. Regulatory compliance and staying prepared for political shifts can mitigate these issues for management.

Transportation And Storage Risks

Transportation and logistics are among the most critical stages of supply chain management. This means they’re also vulnerable to numerous risk factors that could slow down the smooth flow of goods. Furthermore, since transport involves a customer aspect, reduced time efficiency risks reputational damage for delayed, incorrect, or non-deliveries.

Common transportation issues include vehicle breakdowns, a shortage of truck drivers or couriers, shipping setbacks from freight carriers, and delayed order fulfillment. These transport risks could impact delivery and inventory storage at warehouses and distribution centers. This is especially the case for time-sensitive products such as perishable items and materials that can be damaged, spoiled, or lost quality if stored for too long.

Financial Risks

The status of an economy, both domestically and globally, poses significant financial risks to supply chain management. This includes economic instability and uncertainty, exchange rates, interest rates, and currency value fluctuations.

These changes can lead to increased labor and material processing costs, budget overruns, lower profit margins, and supplier bankruptcy. Another financial risk is when operational interruptions affect manufacturing and transportation, which can put supply chains behind schedule. This can be machine breakdowns, shortage of components, quality defects, skilled labor shortage, cargo theft and low product demand.

Environmental Risks

Environmental factors can affect supply chain management in three ways: weather conditions, worker leave and labor disruptions, and sustainability commitment. Extreme weather conditions that include natural disasters, catastrophes, and earthquakes can result in operational and shipping delays due to closures of supply routes, infrastructure damage, and equipment failure from suppliers and manufacturers.

Then, workers exposed to hazardous conditions or accidents during manufacturing and transportation could lead to labor disruptions as they take health leave. Finally, the impact on ecology is also an environmental risk. Supply chain management must comply with global regulations to improve sustainability, protect natural resources, and reduce waste to avoid incurring lawsuits and consumer boycotts.

Manufacturing Risks

Manufacturing risks involve any issues that could arise during the production phase of supply chain management. They can cause disruptions, delays, and a company’s inability to meet product demand.

These include labor and raw material shortages, difficulty procuring raw materials, machine breakdowns, or missing crucial components involved in making a product. Manufacturers supplying food companies face risks of safety and quality while those that produce high carbon emissions and waste to create goods might need to change manufacturing practices to comply with environmental laws.

Conclusion on Common Risks In Supply Chain

Supply chain management involves a complex system of businesses, suppliers, manufacturers, and logistics that work together to deliver goods worldwide. This makes it particularly vulnerable to internal and outside risks that can jeopardize any part of the chain.

The most common include financial, transpiration, environmental, security, and geopolitical factors that impact daily operations. Thus, an important part of supply management is conducting risk assessments to mitigate or resolve these issues and maintain a smooth movement of goods and services.

Managing these risks requires a proactive approach that includes risk assessment, contingency planning, supplier vetting, and continuous monitoring of the supply chain. By identifying and addressing these risks, businesses can improve their supply chain resilience. And protect themselves from potential disruptions and losses.

11+ years strategic communications, marketing, and project management experience. I am a trainer at StarWood Training Institute, focusing on online courses for project management professionals.