Harnessing the Power of Predictive Analytics and Machine Learning in Software Solutions

In the intricate dance of supply and demand, logistics plays the lead role. It’s the silent pulse behind every product shipped, every warehouse stocked, and every online order that lands on a doorstep. But what if we could anticipate the rhythm, predict the next move? This is where the art of logistics meets the science of software solutions. As we dive into this relationship, let’s explore how predictive analytics and machine learning not only join the dance but also choreograph entirely new routines.

Table of Contents

The Significance of Logistics in Software Solutions

Logistics isn’t just about moving goods; it’s a critical web of decisions that affect cost, timing, and quality across industries. Software solutions have become the backbone of modern logistics, offering tools for tracking, managing, and optimizing the flow of products from origin to consumer. The importance of logistics in the digital age cannot be overstated, with e-commerce giants and small businesses alike relying on sophisticated software to meet the demands of a fast-paced world.

We live in a data-driven era where past patterns illuminate future trends. Predictive analytics sifts through historical data to forecast what might happen next, turning hindsight into foresight. In the realm of logistics, this means predicting consumer demand, shipment delays, or inventory needs before they become pressing issues. Embedded within software solutions, predictive analytics stands as a sentinel, offering a glimpse of what the future might hold.

Understanding Predictive Analytics in Logistics

Predictive analytics, a crystal ball in the realm of data science, plays a pivotal role in transforming logistics operations. But what exactly is predictive analytics? In essence, it refers to the use of statistical algorithms and machine learning techniques to identify the likelihood of future outcomes based on historical data. It’s like having a time machine for your data, allowing businesses to anticipate events before they happen, enabling proactive decision-making.

Defining Predictive Analytics and Its Role in Optimizing Logistics Operations

Imagine being able to foresee potential delays in shipping, anticipate demand spikes for products, or predict inventory shortages before they occur. This is the power of predictive analytics at work in logistics. By analyzing patterns in data from various sources – including past shipment records, weather reports, and market trends – companies can forecast future events with remarkable accuracy. This forward-looking approach helps optimize the entire supply chain, from inventory management to delivery schedules, ensuring that goods are at the right place, at the right time, in the right quantity.

Exploring Real-World Examples of How Predictive Analytics Can Be Applied in Software Solutions for Logistics

Let’s bring predictive analytics to life with real-world examples. Consider a major online retailer using predictive models to stock warehouses before a big sale event. By analyzing previous sales data, social media trends, and local events, the retailer can predict which products will be in high demand, minimizing stockouts and overstock situations. Another example is a shipping company leveraging weather forecast data to reroute vessels proactively, avoiding delays and reducing fuel consumption.

Moreover, logistics software imbued with predictive analytics can offer dynamic pricing models. For instance, a freight company may adjust shipping rates in real-time based on anticipated changes in supply and demand, thus maintaining competitive edge while maximizing profit margins.

Discussing the Benefits of Using Predictive Analytics, Such as Improved Efficiency and Cost Savings, in Logistics Management

The advantages of integrating predictive analytics into logistics are numerous. At the top of the list is improved efficiency. By predicting potential roadblocks and demand surges, companies can prepare and adapt quickly, thus streamlining their operations. This not only saves time but also significantly reduces the cost associated with excess inventory and expedited shipping.

Cost savings also come into play through better resource management. For example, by forecasting the optimal amount of product needed at different times, companies can reduce waste and storage costs. Predictive analytics also enhances customer satisfaction by ensuring on-time delivery and availability of products, which in turn can lead to increased loyalty and repeat business.

Unpacking Machine Learning in Software Solutions

As we delve deeper into the digital transformation of logistics, it’s essential to understand the bedrock of advanced software solutions—machine learning (ML). But what exactly is ML, and how does it play a pivotal role in the logistics industry? Simply put, machine learning is a subset of artificial intelligence that enables software to become more accurate in predicting outcomes without being explicitly programmed to do so. It learns from patterns and experiences, much like humans do, but at a scale and speed that are incomprehensible to us.

Machine Learning Fundamentals and Logistics Applications

At its core, machine learning uses algorithms to parse data, learn from that data, and then make a determination or prediction about something in the world. In logistics, this translates to smarter systems that can, for instance, predict when a truck will arrive at a warehouse or anticipate inventory shortages before they become problematic. By integrating ML into logistics software, companies can preemptively address potential disruptions, leading to smoother operations.

Automating Decision-Making in Logistics

The beauty of incorporating machine learning into logistics software lies in its ability to automate decision-making processes. This not only reduces human error but also frees up valuable time for logistics professionals to focus on strategy and customer service. For example, by analyzing vast amounts of data, an ML algorithm can recommend the most fuel-efficient route for delivery trucks, or it can optimize the loading of cargo based on weight distribution, size, and destination points.

Transformative Case Studies in Logistics

Let’s look at some transformative case studies where ML has significantly impacted logistics operations:

- Predictive Maintenance: One transportation company implemented machine learning to predict vehicle maintenance needs. Sensors on vehicles collect data in real-time, which ML algorithms analyze to forecast potential breakdowns. This proactive approach has led to a reduction in unplanned downtime and significant cost savings.

- Demand Forecasting: A retail giant uses ML to predict product demand at different times of the year. By analyzing past sales data, social media trends, and local events, their system accurately stocks inventory before peak shopping periods, reducing waste and increasing revenue.

- Route Optimization: A courier service integrated ML into their dispatch system to optimize delivery routes in real-time, considering traffic patterns, weather conditions, and delivery windows. This has culminated in faster delivery times and higher customer satisfaction rates.

These examples highlight just a few ways machine learning is revolutionizing the logistics sector. By leveraging such powerful technology, companies can harness the full potential of their data, making informed decisions that lead to operational excellence. The ripple effect of these innovations is felt across the entire supply chain, enhancing efficiency, reducing costs, and ultimately delivering a better experience for the end customer.

Integrating Predictive Analytics and Machine Learning for Enhanced Logistics Performance

Imagine a world where the vast complexities of logistics operations are streamlined to the point of near perfection. This isn’t a far-off fantasy; it’s the potential reality when we harness the combined power of predictive analytics and machine learning. But how exactly does this integration lead to more robust predictions and actionable insights?

The Synergy of Predictive Analytics and Machine Learning

Predictive analytics and machine learning are akin to a dynamic duo in the world of logistics. Together, they sift through historical data and identify patterns that humans might overlook. Predictive analytics uses statistical techniques to forecast future events, while machine learning continuously improves its predictions as it encounters new data. The result? A logistics platform that not only predicts what will happen but also adapts and learns how to make even more precise predictions over time. For instance, this could mean accurately forecasting inventory needs for the next quarter or anticipating potential disruptions in the supply chain before they occur.

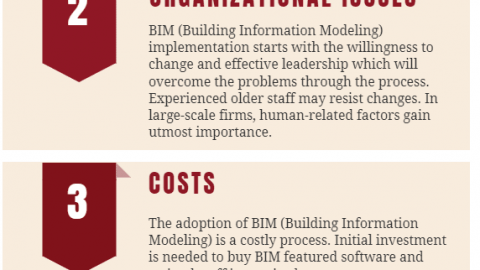

Navigating Challenges in Integration

However, integrating these advanced technologies into existing systems is not without its challenges. Compatibility with legacy software, data privacy concerns, and ensuring the quality and cleanliness of the data used for training models are among the hurdles that need to be overcome. Moreover, the adoption of these technologies requires a cultural shift within organizations, emphasizing the importance of data-driven decision making and continuous learning. It’s a journey that involves meticulous planning, a willingness to experiment, and a commitment to ongoing education and training.

Transforming Supply Chain Management

When predictive analytics and machine learning are effectively integrated, the impact on supply chain management can be profound. These technologies enable companies to be more proactive rather than reactive. For example, by analyzing weather patterns, social media trends, and geopolitical events, logistics platforms can predict and mitigate risks, such as shipment delays or sudden spikes in demand. This proactive approach not only enhances efficiency but also contributes to a leaner and more responsive supply chain.

Optimizing Inventory to Meet Demand

Inventory optimization is another area ripe for transformation. Predictive analytics can forecast demand with high accuracy, allowing companies to maintain optimal stock levels. This reduces the capital tied up in inventory and minimizes storage costs. Meanwhile, machine learning algorithms can identify the most efficient methods of inventory replenishment, leading to a reduction in stockouts and overstock situations. The end result? A tighter, more efficient inventory system that saves money and satisfies customers.

Boosting Customer Satisfaction

Ultimately, the goal of any logistics operation is to ensure customer satisfaction, and the integration of predictive analytics and machine learning is a game-changer in this arena. With more accurate delivery times, reduced risk of product unavailability, and the ability to anticipate and address issues before they affect the customer, these technologies are reshaping the customer experience. Happy customers mean repeat business and positive word-of-mouth, which are invaluable in today’s competitive marketplace.

Conclusion

As we cross the finish line of our enlightening journey through the landscape of logistics, it’s essential to revisit the peaks of insight we’ve scaled together. The integration of predictive analytics and machine learning has indeed reshaped the terrain of logistics, optimizing a field that is foundational to the global economy. Reflecting on the key takeaways from our discussion, let’s underscore the transformative power these advanced technologies wield in the realm of supply chain management.

Predictive analytics has emerged as a beacon, guiding logistics operations towards unprecedented levels of efficiency. By analyzing historical data, this technology allows companies to anticipate future events and trends, empowering them to make informed decisions. The real-world examples we’ve delved into have illustrated how predictive analytics can be harnessed within software solutions to save costs and time, while significantly reducing waste and improving customer satisfaction.

Machine learning, the intellectual partner of predictive analytics, brings its own set of tools to the table. It extends the capabilities of software solutions, enabling them to learn from data and improve over time without explicit programming. This adaptive nature of machine learning algorithms has automated decision-making processes and provided robust solutions for challenges such as predictive maintenance, demand forecasting, and route optimization.

The synergy between predictive analytics and machine learning is not just additive; it’s multiplicative. When combined, these technologies amplify each other’s strengths, leading to more accurate predictions and actionable insights that drive enhanced logistics performance. This powerful integration has the capacity to transform every facet of the supply chain, from inventory optimization to overall customer experience.

Yet, the path to implementing these advancements is not without its hurdles. Compatibility issues, data quality concerns, and the need for cultural adaptation within organizations are some of the challenges that businesses face. However, those who navigate these challenges successfully unlock a new echelon of operational excellence.

In conclusion, the impact of integrating predictive analytics and machine learning into logistics cannot be overstated. This digital metamorphosis ushers in an era where ‘Logistics 2.0’ is not just a buzzword but a tangible reality, offering a competitive edge to those who embrace it. As we close this chapter, remember that the logistics landscape is continually evolving, and staying ahead means remaining adaptable, informed, and ready to leverage the full potential of these groundbreaking technologies.

Frequently Asked Questions

1. What is the significance of logistics in software solutions?

Logistics plays a crucial role in software solutions by optimizing operations such as transportation, inventory management, and supply chain coordination. Software solutions enhance efficiency, reduce costs, and improve customer satisfaction in logistics management.

2. What is predictive analytics, and how does it apply to logistics?

Predictive analytics involves using historical and real-time data to forecast future events or outcomes. In logistics, predictive analytics helps optimize routes, anticipate demand, prevent disruptions, and enhance decision-making processes.

3. What are some real-world examples of how predictive analytics is applied in logistics software solutions?

Examples include route optimization for delivery fleets, demand forecasting for inventory management, predictive maintenance for equipment, and risk assessment for supply chain disruptions.

4. What are the benefits of using predictive analytics in logistics management?

Benefits include improved efficiency through optimized operations, cost savings from reduced waste and better resource allocation, enhanced decision-making based on data-driven insights, and increased customer satisfaction through reliable and timely deliveries.

5. What is machine learning, and how is it utilized in logistics software solutions?

Machine learning is a subset of artificial intelligence that enables systems to learn from data and make predictions or decisions without explicit programming. In logistics, machine learning automates decision-making processes, identifies patterns in data, and improves forecasting accuracy.

6. Can you provide examples of machine learning applications in logistics?

Examples include route optimization algorithms that adapt to changing traffic conditions, dynamic pricing models that adjust based on demand fluctuations, and recommendation systems for inventory replenishment based on historical sales data.

7. How do predictive analytics and machine learning work together to enhance logistics performance?

Predictive analytics provides insights into future events or outcomes, while machine learning algorithms analyze data to make real-time decisions and optimize processes based on those insights. Together, they enable proactive decision-making and continuous improvement in logistics operations.

8. What challenges are associated with integrating predictive analytics and machine learning into logistics software solutions?

Challenges include data quality and availability, interoperability between different systems and data sources, the need for skilled data scientists and analysts, and ensuring transparency and trust in automated decision-making processes.

9. How can logistics software solutions transform supply chain management?

Logistics software solutions optimize inventory management to meet demand, streamline transportation and distribution processes, and enhance visibility and coordination across the supply chain, ultimately improving efficiency, reducing costs, and boosting customer satisfaction.

10. What are the key takeaways regarding harnessing predictive analytics and machine learning in logistics software solutions?

By leveraging predictive analytics and machine learning, logistics companies can gain valuable insights, automate decision-making processes, optimize operations, and ultimately achieve greater efficiency, cost savings, and customer satisfaction in supply chain management.

With more than 20 years of progressive experience as Program Manager and Project Manager had led complex IT projects/programs in a wide variety of industries in America, Latin America & Italia.

Mario Bisson Andini is an advanced Program Manager who is the founder of Bisson Training.