Key Types Of Software Every Manufacturer Should Be Aware Of

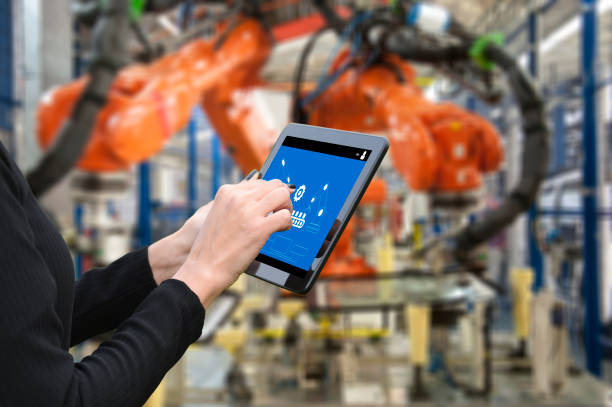

When operating within the manufacturing industry, there will be various types of key software you should implement to improve certain processes. This software will help you gain more control over how your goods are manufactured. Many manufacturing businesses will benefit from software to help them design and create goods. This wasn’t always the case for manufacturing businesses, as they used to be quite traditional. These modern days, it has become more digital.

Table of Contents

Some of the software we will go over in this list will be useful specifically for software for manufacturing industry. And some of these types of software will be useful for all businesses. For example, inventory management software would be useful for you to keep on top of your stock. With all this said, let’s get stuck in.

MRP Software

Materials requirements planning software is a system that allows your manufacturing business to work out how many raw materials will be required for you to meet customer demand. This smart type of software can make instant calculations based on your current orders and upcoming orders, as well as make some projections in some cases.

This will help ensure you always have the stock you need to meet demand, and will automate some processes such as issuing work orders and completing purchases. Not only will this see your manufacturing business save time, it will also reduce the number of human mistakes that are on hand.

MRP software is planning software that automates and helps keep your business going. There are plenty of different variations of MRP software. So you have more choice in how much automation you want to implement.

Cloud Manufacturing Software:Innovation Types of Software

One of the biggest innovations for the manufacturing industry in recent years is cloud manufacturing software. Businesses that use cloud manufacturing software will be businesses that save on investing in their own IT infrastructure. This means that they won’t have to pay the initial cost for setting it up and won’t have to pay high amounts of running costs.

Of course, it largely means you don’t need to have hardware on hand to run your software. You may still need some personal devices to host them, such as a phone or laptop, as well as an internet connection, otherwise you’re ready to go.

Cloud manufacturing software may also be known as software as a service and is one of the largest market segments when talking about cloud-based software. This is something that will only continue to grow, as it offers manufacturing businesses big savings on their software as well as their hardware.

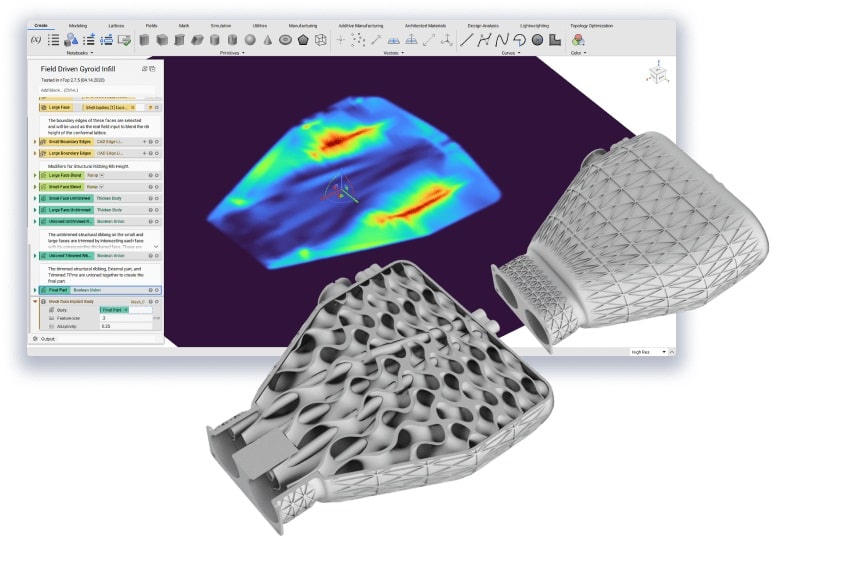

Lattice Generation Software

Manufacturers, particularly those working within the engineering industry, should be aware of lattice generation software. Lattice generation software will help to create intricate lattice structures that could have a variety of uses. They could be used to create lightweight structures. They are helping you to minimize the weight of your product and material usage for a variety of industry uses. This would be important for pieces in the aerospace, medical or automotive industry.

Lattice structures in Types of Software

Lattice structures can also be used to help create custom 3D printed foams that allow for high-porosity lattice structures. The products that are designed through smart lattice generation software will be much more highly detailed and allow for slick unique designs that are exactly to your specifications.

There are a few different lattice structure types that can be designed through this type of manufacturing software. They come in the form of beam, honeycomb, stochastic, and TPMS. Beam will be useful for lightweight structures that need a high amount of damage tolerance and energy absorption. Honeycomb structures will have some of the highest directional stiffness that can be generated, with allows for planar lattice structures. A stochastic generation will be useful for porous foam-like structures, which also have a variety of applications. Finally, TPMS will be used for structures that require a large surface area. This unit cell type will allow for high stiffness and offers excellent manufacturability.

Smart lattice generation software will prove to be useful for any manufacturing business or someone looking to get involved in the industry. You should ensure you have all the tools you need to work with lattice generation. nTopology offers a toolset that allows for performance-driven lattice structures for advanced engineering purposes. This will allow you to achieve next-level product performance during the manufacturing stage. The toolset will give you tools to help design the highest-performing parts you need for additive manufacturing.

Contact Management Software

Manufacturing software doesn’t just need to relate to the physical process of manufacturing. It could also refer to processes that help the business in general. That’s where contact management software will come in. As a manufacturing business, you will likely have a range of people and businesses you connect with. It may be suppliers you get raw materials from, or the businesses you sell your finished manufactured goods to.

Due to all the different contacts that you have within your network, you should look into acquiring a contact management system. This type of software will allow you to effectively store and organize the contact details of every business you work with. This prevents you from misplacing information or sending manufacturing invoices off to the wrong person.

Essentially, it will help you appear to be more professional with your supply chain and your network in general. You can automate the processes to keep up-to-date records for your customers and suppliers, which helps you keep your business relationships healthy and boosts your business overall.

Accounting Software

Manufacturing businesses will be conducting a lot of financial transactions. As such, it will benefit manufacturing businesses to look into using accounting software. This type of specialized software will help a manufacturing business record all the incomings and outgoings for your finances. This type of software will also allow you to record your expenses from within the company. They are also ensuring you aren’t missing anything and gaining more control over your finances.

Accounting software helps you ensure that you aren’t misplacing transaction data. If you still have paper-based records, then you will be familiar with how painful it can be to find transaction information when you need it. Having a good software will allow you to have multi-capabilities.

This helps keep your business more structured and organized, offering more opportunities. Not only will you save time on gathering data, but you will also be able to clearly identify any wasted funds and correct them. You may find that there are funds on manufacturing goods to spend better. Overall, it will give you a clear picture of your manufacturing business’ financial health, which will help you make a more informed decision.

Budgeting Software

In a similar line of thinking, you may be able to protect your finances and gain more financial control by using budgeting software. Manufacturers will always have a lot of expenses in order to operate and manufacture what they manufacture. You should have a set limit of what you expect to spend each year to protect yourself against potential financial ruin further down the line.

It can be hard to budget everything yourself, especially as your business grows. That’s why these businesses should be looking into budgeting software. As it enables businesses to log all of their costs and allow them to predict future costs. Essentially, it allows you to analyze your typical spending from previous years. So that you can get a good insight into your future trends.

Budgeting software can automate a lot of the budgeting software, especially with the analysis and analytics in general. You will also be able to use this budgeting software in a flexible way too. For example, you will be able to amend your budget through the software, with digital solutions being able to do it all seamlessly no matter what variables there are.

Quality Control Types of Software

On a final point, it’s worth being aware of the quality control software that is out there for software for manufacturing industry. As you can imagine, this will be incredibly useful for a manufacturing business. As they will be able to ensure everything is up to their required standard before being able to sell it.

While in the past, you would have to manually inspect everything for quality control. There is now software available that can assist. This software can work with quality metrics that help look out at various stages of the production process. This will allow the system to find any issues at every stage of the production process.

This includes sourcing the materials from the start to the finished manufactured product. If you don’t have this sort of software in place and you produce lower-quality goods, you will have a disappointed customer base and lose out. Quality control software allows you to get on top of any little mistakes. And ensure you are running at 100% efficiency or as close as possible. Essentially, you should be implementing this, and any of the software mentioned in this article, to improve performance levels.

Business Developmeny Manager at PAS InfoCom Technologies Ltd. Experienced in project management with a demonstrated history of working in the information technology and services industry.