While evaluating the results after taking data measurements, you need to bear in mind two significant concepts that are accuracy and precision. Your data set might be close to an accepted value or it might be completely different from an anticipated result. So how can you point out if the measurements are close to the target or not? The main difference between accuracy and precision is that accuracy indicates how your measurement is close to a specific value, while precision shows how measurements are close to each other in a cluster. Here we will discuss the topic of accuracy vs precision with examples to show you how to use both concepts in project quality management.

Table of Contents

Accuracy and Precision

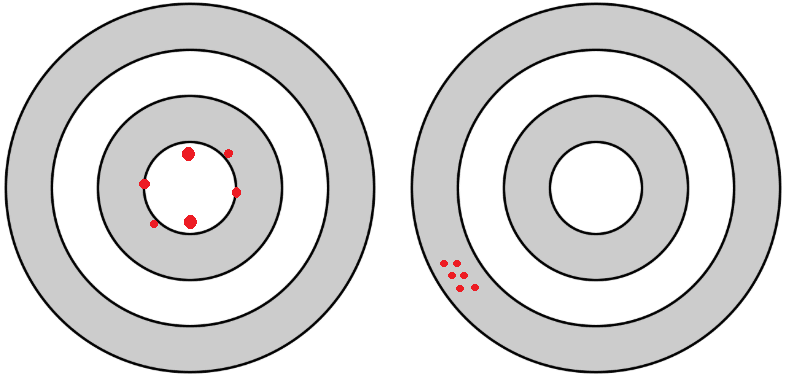

Before to start, let’s take a glance at the image below.

Assume that you played dart with your friends. You and your friend hit the target shown in the images above. The image on the above left demonstrates a high degree of accuracy, but low precision. On the other hand, the image on the above right demonstrates high precision, but low accuracy.

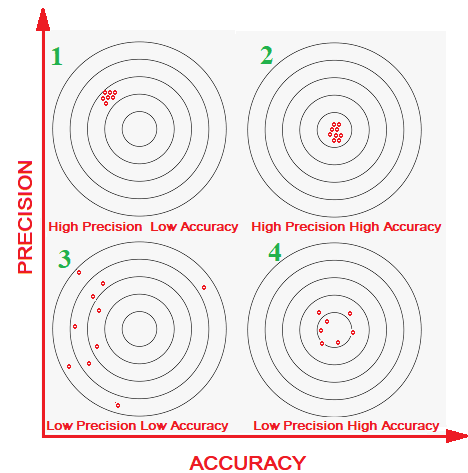

For better understanding, let’s analyze the image below;

Figure 1

Your measurements are close to each other but they are far from the target value. This shows high precision but low accuracy.

Figure 2

Your measurements are close to each other and they are on the target value. This shows high precision and high accuracy.

Figure 3

Your measurements are far from each other and they are far from the target value. This shows low precision and low accuracy.

Figure 4

Your measurements are far from each other but they are close to the target value. This shows low precision but high accuracy.

What is Accuracy?

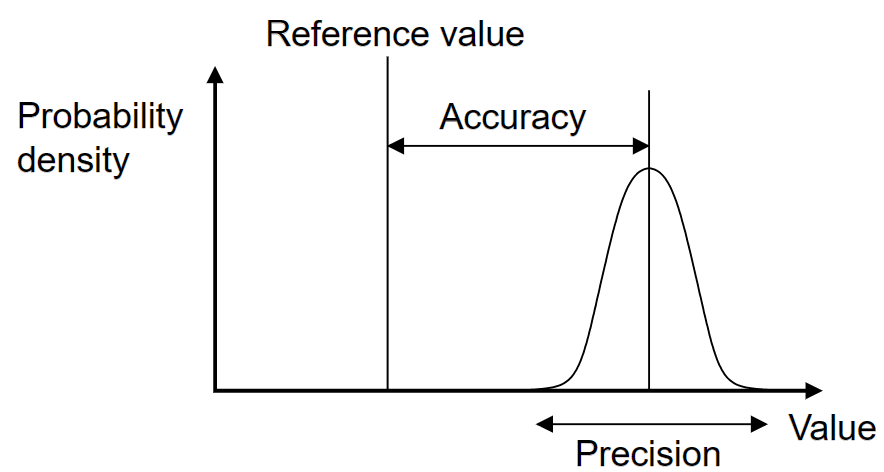

The below figure shows that the closeness of a measurement to the true value is Accuracy while the closeness of agreement among a set of results shows precision.

Accuracy means the values gathered from repeated measurements are close to the target. If all the measurements are accurate, this means that they are close to the target and they may be or may not be close to each other.

For instance, you are working as a technician in a laboratory. You measured the weight of a given substance which was 4 kg. However, the known or actual weight of it must be 20 kg. You can easily say that your measurement is not accurate because is not close to the known value.

What is Precision?

Precision means the values gathered from repeated measurements are close to each other in a cluster. They have little scatter.

If all the measurements very precise, it means that the measurements are close to each other and they may be or may not be close to the target. When the scatter is less, measurements have high precision.

Considering the same example above, you measured the weight of a given substance three times and you listed the results;

- Measurement 1: 3.9 kg

- Measurement 2: 4.4 kg

- Measurement 3: 5 kg

You can easily say that your measurement is very precise. However, it is not accurate. Precision is not dependent on accuracy. You can be precise but not accurate vice versa you can be accurate but not precise.

Accuracy and Precision Example

Assume that you are a quality manager of a pipeline construction project. The warehouse received 1000 pipes from the supplier. According to the technical specifications, the thickness of each pipe must be 30 millimeters. In order to make an inspection, you randomly take the thickness measurements of five pipes.

Pipe Thickness

- First pipe: 30.50 mm

- Second pipe: 30.55 mm

- Third pipe: 30.58 mm

- Fourth pipe: 30.45 mm

- Fifth pipe: 30.47 mm

The inspection result shows that the measured values are precise but not accurate. Because all the measurements are close to each other but they are not close to the desired value of 30 millimeters.

Below is another measurement for the same batch. You randomly take the thickness measurements of five pipes.

Pipe Thickness

- First pipe: 29.90 mm

- Second pipe: 29.85 mm

- Third pipe: 30.10 mm

- Fourth pipe: 30.15 mm

- Fifth pipe: 29.87 mm

This simple example shows that the measured values are accurate but not precise. Because all the measurements are close to the desired value of 30 millimeters but they are not close to each other.

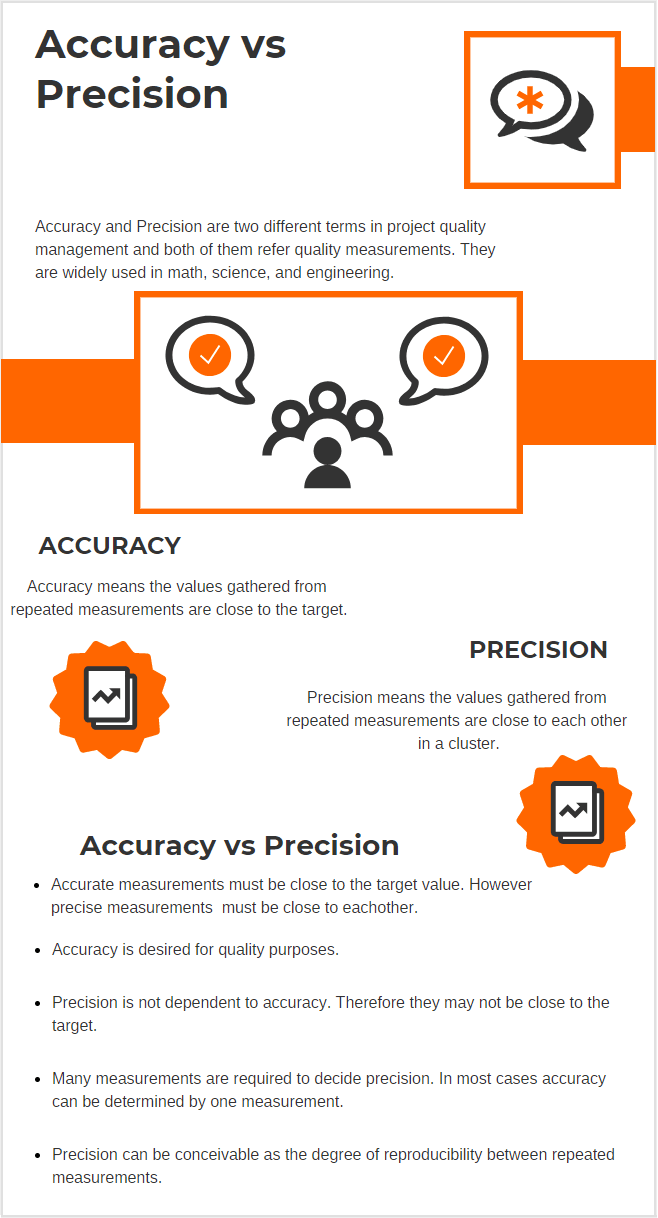

What is the Difference Between Accuracy and Precision?

- Accurate measurements must be close to the target value. However precise measurements must be close to each other. They don’t have to be close to the target value.

- Accuracy is desired for quality purposes.

- Precision is not dependent on accuracy. Therefore they may not be close to the target.

- Many measurements are required to decide precision. However, you need fewer measurements to decide accuracy. In most cases, accuracy can be determined by one measurement.

- Precision can be conceivable as the degree of reproducibility between repeated measurements.

Summary

Accuracy and Precision are two different terms in project quality management and both of them refer to quality measurements. They are widely used in math, science, engineering, and project management to analyze data sets. Precision states that the measurements are consistent with very little variation and Accuracy states that the measurements are close to the desired value and they are correct. A Precise measurement does not mean accurate and an accurate measurement does not mean precise.

In this article, we discuss the concept of accuracy vs precision in quality management and show how to calculate them with examples. We hope that all the points are clear and it will be useful to understand their importance for quality management purposes. If you would like to share your knowledge or add something, you can do so through the comments section below.

Please note that these terms are also very important from a PMP Certification Exam point of view; therefore, you must know the definition of these concepts and understand the difference between them.

See Also

Since 2004 I work for ICT Management which provides worldwide quality management service. Passionate about new technologies, i have the privilege to implement many new systems and applications for different departements of my company. I have Six Sigma Green Belt.