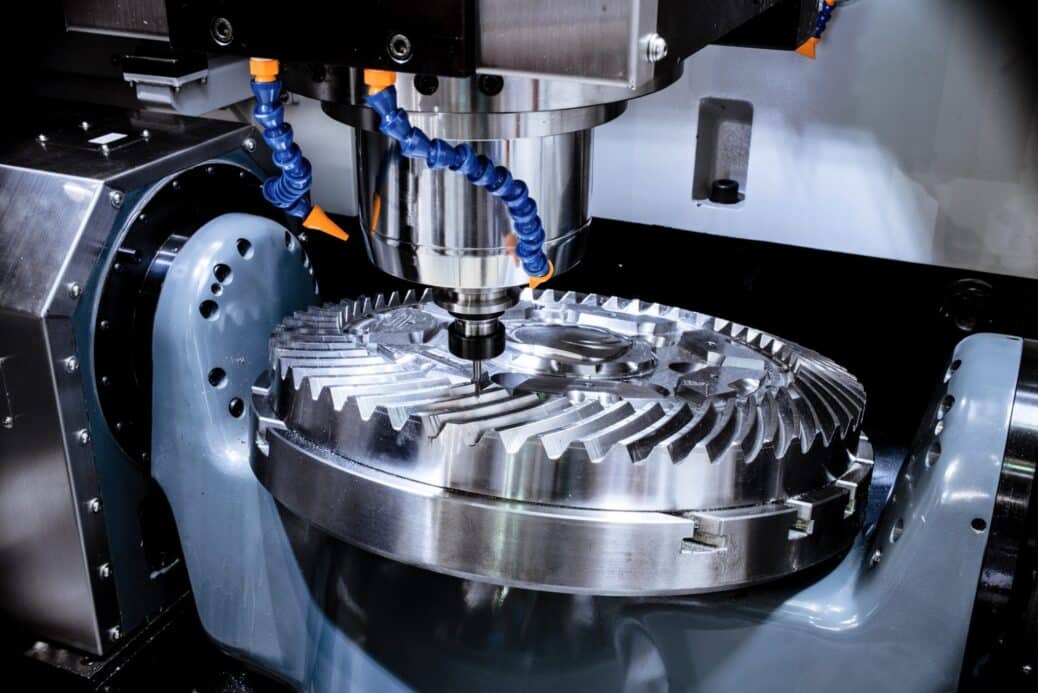

What Makes CNC Machining the Best Option for Rapid Prototyping?

Rapid prototyping is a critical stage in the process of developing a product. Prototypes of products are used to comprehend the design, spot manufacturing flaws better, and assess the potential for failure within the product design cycle. It is crucial to prevent flaws and failures during production to avoid significant financial losses and product recall. And you need to choose the cnc machine for rapid prototyping.

Table of Contents

What is Functional Prototype Manufacturing?

We’re asked about functional prototype manufacturing, so we’ll define it. Manufacturing differs from other “manufacturing” by volume. Manufacturing works in large quantities. Because prototypes are works in progress and are usually come in small quantities. Functional prototype manufacturing implies making a suitable quantity of high-quality product prototypes for market testing or certification.

Different sorts of prototypes, including dummy prototypes, functional prototypes, structural prototypes, etc., are produced in industries. Although several production methods can work to create these prototypes, there are significant differences in the manufacturing times and prices. Rapid prototyping mostly operates by using CNC machining. What makes it a common decision? This article covers solutions to this question and others.

The Fundamentals Of Rapid Prototyping

In rapid prototyping, the following factors are crucial. These requirements should meet with production technique for the prototype.

Design Flexibility with CNC Machining for Rapid Prototyping:

Rapid prototyping methodologies must take design flexibility into account. The production technique should work with a variety of designs.

Machinability:

Complicated features should be machinable. The same part should be able to be machined using the tool of choice.

Material Compatibility:

Choosing the right materials is crucial in the prototyping process. Since the prototype and ultimate product frequently share the same material, the machining method should work with the material of choice.

Precision and Accuracy in Dimensions:

When prototyping, accuracy and precision in dimensions are crucial.

Repetition is Easier with CNC Machining for Rapid Prototyping:

If numerous prototypes will be in production, repeatability is another critical issue. This aids production in bulk.

These core requirements for rapid prototyping are all satisfied by CNC machining. Manufacturers gain from it in several ways. You can see the detailed info after this section.

Advantages of CNC Machining for Rapid Prototyping

CNC

-

CNC machining is fast-

This notion speeds up prototyping. CNC milling prototypes work automatically after loading the CNC software and CAD design. Producing many prototypes is simple.

-

CNC allows tool versatility-

Without stopping production, tools can vary. CNC machining uses single-point cutting, drilling, tapping, milling, and more.

-

CNC machining is precise. Lowest tolerance-

This method readily achieves the requisite dimensional accuracy. CNC components rarely need polishing. Therefore their dimensional accuracy does not change.

-

Design-based CNC production cycle changes-

Several ways can create one feature. Depth cutting or grooving generates grooves. Programming allows CNC machining method selection.

-

CNC machining cuts metals and plastics-

Thus, it is the finest for fast prototyping in all industries.

No fixed tooling is required for CNC Machining for Rapid Prototyping

Rigid dies composed of steel alloys that have been hardened or semi-hardened are necessary for several production processes including plastic injection molding and pressure die casting. Depending on the intricacy of the tools, it might often take several weeks to make them. Even vacuum casting involves silicone molds, the creation of which might take many days. For many tasks, this is obviously completely worthwhile. And particularly when recreating delicate surface patterns that were from a master design. On some applications, however, where CNC machining creates a smoother and flatter surface for items. Hence, that could be a limiting issue.

The sharpened metal working inserts in the spindle are the sole tools for CNC turning and milling. Yet, cutting components of different sizes and kinds cut the workpiece in a variety of ways. But when organized appropriately on an automated turntable, these tools may be quickly changed out and exchanged.

Modifying CNC Machining is Simple

By merely changing a few lines of the G-code program, it is simple and fast to modify a design. This is particularly appealing for prototyping since it gives you the ability to try out several versions and evaluate the results right away. The entire lead time for product development can be shorter by fine-tuning a software and making improvements “on the fly” without incurring additional costs.

Materials and CNC Machining

As far as the material is hard enough to neither bend or melt under the pressure of the cutting motion, CNC machines don’t care what they are cutting. Additionally, this may be useful when creating a variety of comparable prototypes with slightly varied mechanical or aesthetic qualities. For instance, the identical design can work using hard plastic, aluminum, or steel. But with just minor changes to the speed and feeding of the cutting tool.

Conclusion: Start CNC Machining for Rapid Prototyping

Finally, the above points indicate that CNC machining is the best option for rapid prototyping. So, if you plan to create a prototype of your product, then CNC machining is the best option.How do you choose the best fast prototyping method for your project when CNC machining, 3D printing, metal injection are not all equal?

CNC machining is the best option if you want to swiftly produce large quantities of prototypes with structural integrity and excellent mechanical qualities. In contrast, 3D printing works better for creating limited quantities of prototypes that are for illustrating ideas.

Prototypes of injection molding and urethane casting, which combine the structural stability of CNC machining and the excellent surface polish of 3D printing. However, they have expensive tooling and protracted lead times for setup. Yet, they may not be the most affordable choice for modest prototype runs.

Ananya Prisha is an enterprise level Agile coach working out of Hyderabad (India) and also founder of High Level PM Consultancy. Her goal has been to keep on learning and at the same time give back to the community that has given her so much.