One Product Design Mistake Costing You Lots of Time and Money, How to Avoid?

Table of Contents

There are lots of little things that might be making your business a little less efficient than it could be. But one mistake you’re probably making could be costing you an enormous amount of time and money. That is the design of your product or parts. And you probably won’t even know it’s costing you. That’s why design for manufacturability is crucial. What are the most common product design mistakes?

Many manufacturers think developing a new product is like generating a new idea. If you think so, that is just the beginning of a BIG MISTAKE. Before you finalize a product to launch in the market, there are many steps.

You start with an initial sketch. Then you have to create conceptual sketching, design the product, prototyping, error fixing, low volume production, and then final bulk production. You should recognize that every step is very important, and also you can’t skip them.

But don’t worry. There are ways to avoid those design mistakes. This article will help you to avoid those mistakes and make “The Perfect” product from scratch.

How to Avoid the Most Common Product Design Mistakes

A tiny design mistake can cost you a huge amount of economic loss. Product manufacturing is a tricky business. You must understand consumers’ demands and develop a product that fulfills them.

Assessment of Cost, Performance, Aesthetics

Cost, performance, and aesthetics are the three pivotal points of a perfectly designed product. Therefore, you must understand the balance between these three factors.

Create a clear outline of your design goals, along with an explanation of how you intend to achieve them. Learn about your clients to find the optimal combination of cost-efficiency, attractiveness, and performance. And bear in mind, Even if the design is more appealing, customers won’t come back for more or tell their friends not to buy it if the product doesn’t work well. NEVER compromise the product quality.

Be Smart in Early Prototypes

Prototypes are necessary to test your product. You can not measure the performance of your product before customers buy your products. So, try to spend less money on first or second-stage prototypes.

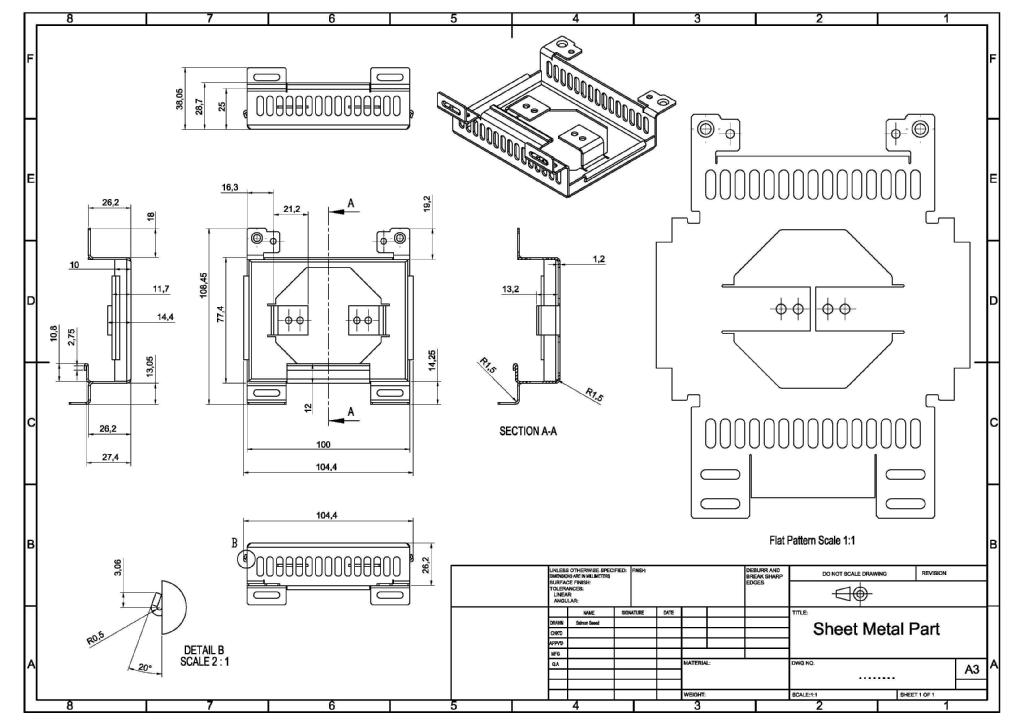

There were several manufacturing processes to do prototypes, like CNC machining, prototype injection molding, sheet metal fabrication, 3d printing etc. Choosing the right process for the prototyping stage would save your time and cost. If you can’t confirm which one you need to use, communicate with some prototyping manufacturer, they would help to give the right answer and such kinds of consults usually are free of charge.

Consider the Final Manufacturing Procedure When Designing to Avoid Most Common Product Design Mistakes

Many designers don’t consider the manufacturing process when designing a new product. They just focus on making something that looks good and is functional. However, this is a big mistake.

So, what is the solution here? A designer must bear in mind how the product is going to be manufactured. The key is to start from the end.

When you want to remove as little material as possible, CNC machining is the ideal process. However, depending on your production quantity, 3D printing or injection molding may be a preferable option if your part has complex geometries.

Furthermore, you can develop the product by applying a hybrid manufacturing strategy. Hybrid manufacturing combines additive (3D Printing) and subtractive (CNC Machining) manufacturing is conceivable. If your design needs both, keep that in mind while designing.

Always Choose Value Over Cost

The heading might be a little bit confusing. Let us clear the confusion. Sometimes, there could be a high initial cost which is necessary for your end product. If you sacrifice the value for the initial cost, you can end up paying more money.

For example, if your product needs certain product development services to avoid product design mistakes and you skip that process for initial costing, there is a high chance that your product will not function perfectly. As a result, you have to run the development process again to identify the problems. Consequently, you will spend more money than the initial cost.

So, never hesitate to pay whenever it is necessary.

Overengineering – Never Do That

Complex engineering always takes a longer time. Moreover, if your product is too complex, that will definitely increase the production cost. Not only production costs but the lead time to create a product will also increase.

Complex engineering is not mandatory for a good product. Keep the internal components simple. Your focus should be on the functionalities of the product. Spend more on testing functionalities. This will ensure every function of your product is working perfectly when you sell them.

Some Other Most Common Product Design Mistakes you should Avoid

- Some products may need certified testing, components, or laboratory verification. If your product falls into that category, tell your manufacturer ahead of time.

- Make sure there is no patent for the product you are trying to develop. You don’t want to develop a product already patented by another person or company. It will be a total waste of time, money, and energy.

- Take expert help when it is necessary. Sometimes, a DIY approach can make the product development process more costly.

- Maintain a proper timeline for the design and development of your product. Talk with your contract manufacturer or supplier frequently and push them to maintain the timeline.

Conclusion

Designing a product is a very complicated task. And a slight mistake in your design can result in a significant economic loss for your company. Besides, if your company launches a badly designed product, that can seriously damage your company’s reputation. So, it is better to follow the proper way to avoid a single mistake that can cost you lots of time and money.

Irma Gilda is chief executive of Sonic Training and Consultancy Co., the training platform offers project planning and scheduling More than 60 k learners have used the platform to attain professional success. Irma is a professional Primavera P6 Trainer.