Lead vs Lag (Lead Time Lag Time) in Scheduling

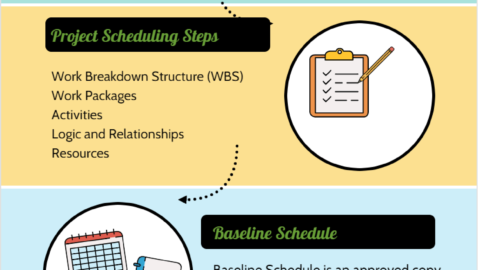

While creating a work schedule or a network diagram, professionals often use many terminologies such as lead time lag time, total float, free float, etc. These scheduling tools are used along with activity relationships in order to model the real nature of work to be performed. Simply put, the main purpose of creating a work schedule is to model the reality and relationships, lead time, lag time, floats are supporting this dynamic model. This article discusses lead vs lag time in project scheduling with the help of examples for understanding the concept easily.

Table of Contents

Lead vs Lag Time

Lead and Lag time are widely used scheduling terms. Project managers and planning engineers always make comparisons between the work schedule and the real work performed on site. Sometimes it may be difficult for them to understand the difference between lead time and lag time while performing schedule analysis.

Many PMP aspirants have difficulty to understand the concepts lead time, lag time, lead vs lag time because they sound quite similar. Therefore, this article will be useful for PMP aspirants and candidates who want to build up a career in project scheduling.

What is Lead Time ?

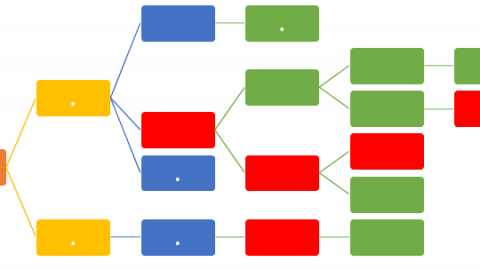

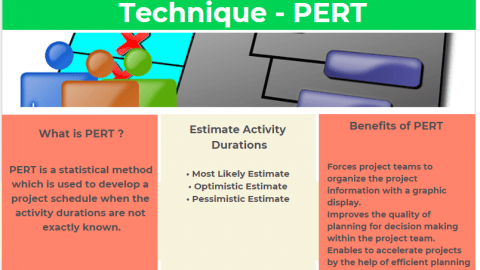

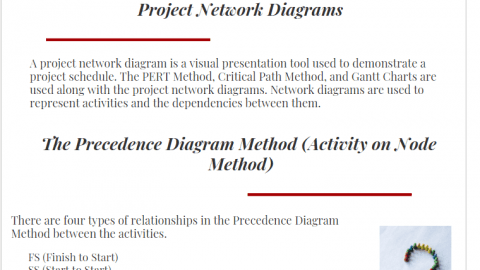

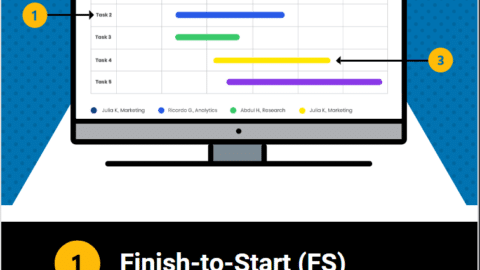

A network diagram is created during the activity sequencing process in project time management. Basically, there are two methods Arrow Diagramming Method (ADM) and Precedence Diagramming Method (PDM) are used for creating network diagrams. Unlike the ADM (Arrow Diagramming Method), the PDM (Precedence Diagramming Method) allows to use four types of activity relationships (FS, SS, FF, SF). Therefore it is the most widely used method for creating network diagrams.

Lead is only found activities with Finish-to-Start relationships. Finish-to-Start relationship means a successor activity can’t start until it’s predecessor finishes. However, in some circumstances, the successor activity may start while the predecessor activity is about to finish.

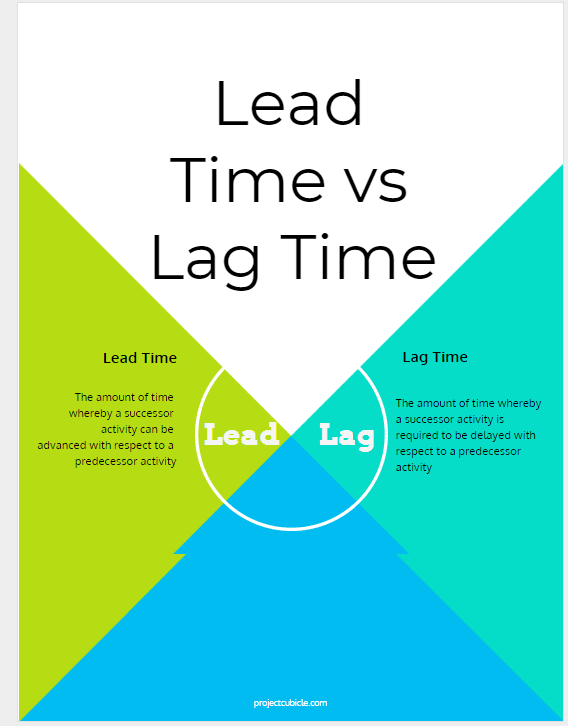

Lead means the beginning of a successor activity before the completion of its predecessor. Lead is the acceleration of the successor activity or simply we can say that lead is the overlap between the predecessor and the successor activity. Lead time can be considered a negative value.

Lead time can also be used in conjunction with schedule compression techniques such as fast tracking.

For better understanding the concept: lead vs lag time, let’s review the example below.

Example for Lead Time

Assume that you are a procurement manager of a steel bridge project and you are planning manufacturing and transportation activities. In your initial plan, relationship between the manufacturing and the transportation activity is Finish-to-Start. In order to accelerate the process, you can start the transportation activity before the completion of all the manufacturing.

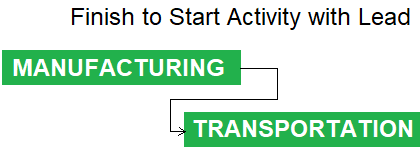

Below figure illustrates two activities that have Finish to Start relationship. The transportation activity is dependent on manufacturing activity. In other words, manufacturing is the predecessor of transportation activity.

Finish to Start Activity with Lead

Another real-life example is as follows ;

Assume that you are building a hotel project and two activities wall cladding and painting have a Finish-to-Start relationship. When you are about to finish the cladding works on the first floor, you start the painting works without waiting all the cladding works are completed.

What is Lag Time ?

Lag is the delay of the successor activity. The successor activity cannot start right after the end of the predecessor activity. In all relationships, Finish-to-Start, Start to Start, Start to Finish and Finish to Finish, lag may be found. Lag time can be considered a positive value. Lag time can be considered as a waiting period or a delay between two activities. For example, we need a waiting time (lag) between plaster and paint of wall.

Example of Lag Time

Below example is important for understanding the lead vs lag concept!

Assume that you are managing reinforced concrete works and you have two activities in a sequence which are rebar and formwork activities. Formwork activity duration is 10 days, rebar activity duration is 5 days. You can use Start to Start + 7 Days Lag.

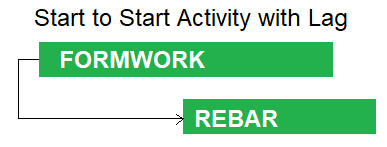

Below figure illustrates two activities that have Start to Start relationship. The rebar activity is dependent on the formwork activity. In other words, rebar is the predecessor of formwork activity.

Start to Start Activity with Lag

Another real-life example is as follows;

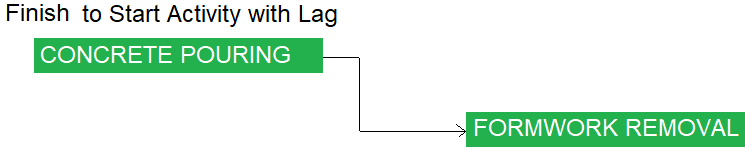

After completion of rebar and formwork, you poured concrete. Now you have to wait for 14 days to remove the formwork. Because concrete strength must be adequate for this process. The relationship between concrete pouring and formwork activity should be Finish to Start + 14 Days Lag.

Finish to Start Activity with Lag

Keystones – Lead vs Lag

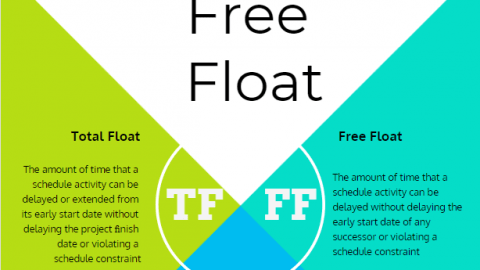

Lead time and Lag time, total float, free float are basic concepts used for the preparation of a project schedule. They are used to create high-quality project schedules which represent the real work to be performed on site. Simply put, project lead time can be considered as a negative value and can be used only with a Finish-to-Start relationship. On the other hand, project lag time can be considered as a positive value and can be used with all kind of relationships (FS, SS, FF, SF). Both of them are used to create functional project schedules that support the team’s decision making.

In brief, lead and lag time are used in conjunction with the relationships (or dependencies) to modify these dependencies.

In this article, we provided lead and lag definition project management and analyzed real-world examples for better understanding. Note that Lead vs Lag time is an important concept for PMP and CAPM Certification Exam. You may encounter one or more than one questions related to the concept.

External Reference

Irma Gilda is chief executive of Sonic Training and Consultancy Co., the training platform offers project planning and scheduling More than 60 k learners have used the platform to attain professional success. Irma is a professional Primavera P6 Trainer.

I like this site very much, it is too helpful and easy understandable. Thanks.