5 Tips on How to Lower Product Design Costs

In product design, it’s not enough that your new product is aesthetically pleasing or functional; it has to be cost-effective to produce as well. After all, price is a major factor in consumer’s buying decisions. This is why the overall cost to make a product is a major consideration for many designers.

Table of Contents

With some innovative thinking and creative execution, product designers can successfully come up with a product design that fits the budget allotted for the project.

For instance, some product designers and developers in New Zealand use a variety of techniques to lower the cost of a product. In fact, if you’re in Auckland, you can search for firms specializing in product design Auckland companies can rely on. With their years of expertise, they can help you find innovative solutions to lower production costs.

Consider the following tips for the next time you’re redesigning your product:

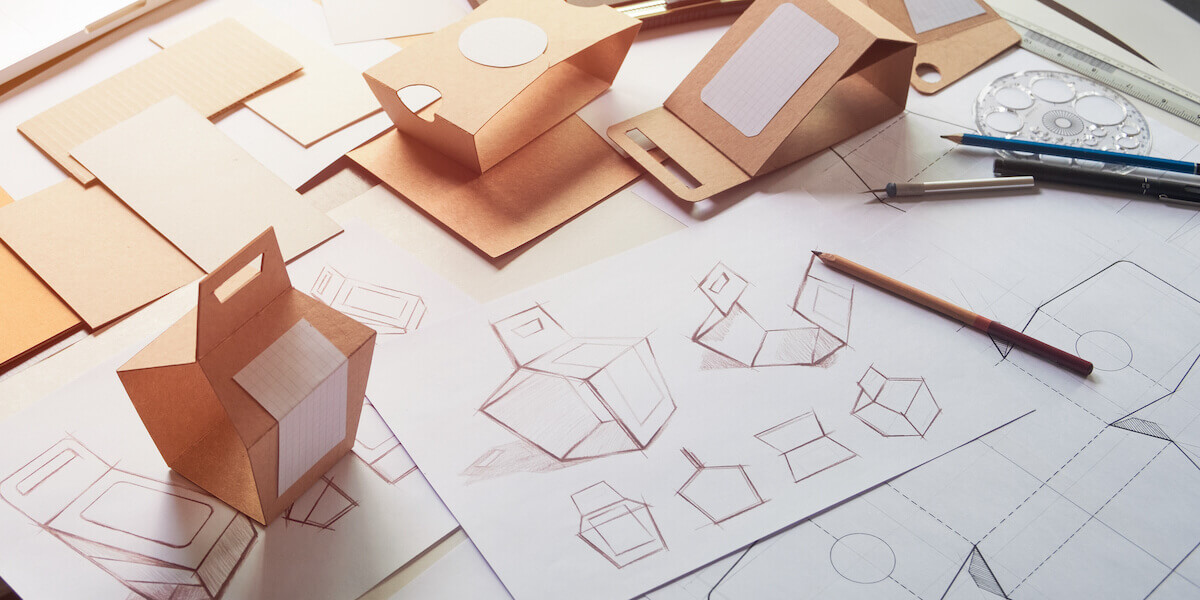

1. Simplify and Streamline the Design

Simplicity is not merely a design principle but a cost-saving strategy as well. Designers can reduce the production time and resources consumed significantly by simplifying and streamlining the design.

Complex product design often requires an increased amount of materials, which may not even impact the functionality of the product. That’s why designers may need to rethink their design and come up with a more streamlined version with reduced material requirements.

A great example of this is the iPod Nano that came out in the mid-2000s. As a pared-down version of the Apple iPod, it was priced significantly lower. This allowed more people to experience having their entire music collection in the palm of their hand.

2. Select More Efficient Materials

The choice of materials can significantly impact both the cost and performance of a product. Designers need to carefully evaluate the materials to strike the right balance between cost-effectiveness, functionality, and sustainability. To do that, they need to conduct thorough material analysis and explore alternative options.

All these lead to substantial cost savings without compromising product quality. Whether it’s opting for recyclable materials or leveraging advances in composite materials, smart material selection is key to lowering design costs.

A good case study of this principle is seen in various smartphone products. Smartphone manufacturers often use a variety of materials to offer a wide range of smartphones at different prices. For instance, their flagship model might be encased in higher price aluminium or glass but the phone models with lower price tags use plastic.

3. Optimize the Production

Efficient production processes are essential for minimising costs and maximising profitability. Designers can optimize production by embracing automation, lean manufacturing principles, and continuous improvement initiatives. These methodologies and approaches can eliminate waste, streamline workflows, and enhance production efficiency. As a result, designers can achieve significant cost reductions while maintaining the product’s high quality and reliability.

It was in the 1950s when Toyota, one of the world’s leading car manufacturers, developed lean manufacturing. Using a strict Japanese work ethic, they came up with strategies that aim to minimize material waste from the car factory. These became known as the 5Ss or 5 principles of lean methodology—Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke). Currently, these principles are being adopted in various aspects of the workplace and not just in manufacturing.

4. Ensure Accurate Product Cost Analysis

Product cost analysis in product design and development involves evaluating the various costs associated with bringing a product to market, including material costs, labor costs, manufacturing expenses, and overheads.

It aims to identify areas where costs can be reduced or optimized without compromising product quality or functionality. By conducting thorough cost analyses throughout the design and development process, businesses can make informed decisions on how to maximize profitability and competitiveness in the market.

Product designers can ensure accurate cost analysis by closely collaborating with cross-functional teams, including procurement specialists, manufacturing engineers, and financial analysts, to gather comprehensive data on material costs, manufacturing processes, and overhead expenses. Additionally, they can leverage advanced cost estimation software and conduct regular reviews throughout the design process to help validate assumptions and refine cost projections for better accuracy.

One notable example of a company that extensively uses cost analysis to produce lower-cost products is IKEA, the Swedish furniture retailer. IKEA is renowned for its affordable yet stylish furniture and home accessories. The company meticulously analyses every aspect of its products’ design, manufacturing, and distribution processes to identify opportunities for cost savings without compromising quality.

5. Factor In the Ease of Production

Design decisions have a direct impact on manufacturing complexity, tooling costs, and assembly time. As such, designers should carefully consider the ease of production during the design phase to minimize manufacturing challenges and associated costs. By designing products with manufacturability in mind, designers can simplify assembly processes, reduce production errors, and ultimately lower design costs.

A prime example of a popular product where the designer accounted for the ease of production is the LEGO brick. LEGO bricks are renowned for their simple yet ingenious design, which allows for easy assembly and disassembly. The interlocking stud-and-tube system, patented by LEGO in 1958, ensures that bricks can securely connect with precision, facilitating effortless building for users of all ages.

From a manufacturing standpoint, LEGO’s injection moulding process is highly efficient and cost-effective. The moulds used to produce LEGO bricks are designed for high repeatability and durability, enabling mass production with minimal variation in quality.

Cost-effective design practices are essential for a successful product launch. By lowering your product’s manufacturing costs, you can enjoy a higher profit margin as well as easily scale up production whenever needed. When redesigning your product, remember these tips to ensure your new product checks all the boxes.

With more than 20 years of progressive experience as Program Manager and Project Manager had led complex IT projects/programs in a wide variety of industries in America, Latin America & Italia.

Mario Bisson Andini is an advanced Program Manager who is the founder of Bisson Training.